FDC-320 Series Mass Flow Controller and Meters

- Full Scale Flow Range: 10sccm-30slm

- Repeatability: ±0.2% F.S

- Control Range: 2%~100% F.S

- Response Time: <2s

- Pressure Coefficient: 0.2% of S.P. / Bar

- Digital Communication:RS-485

- Analog Communication:0~5 V / 4~20mA

Description of FDC-320 Series Mass Flow Controller and Meters

FDC-300 series adopts capillary thermal temperature difference sensor, and the measurement accuracy is not affected by temperature and pressure. The substrate is made of 316L stainless steel, which is suitable for toxic and corrosive gases, and the maximum working pressure can reach 1500 Psi. Digital measurement control circuit, stronger anti-interference ability, digital communication compatible with analog signal 0~5V/4~20mA, electrical interface part adopts surge suppression and overvoltage and overcurrent protection circuit to ensure stable and reliable operation of the system. The FDC series has passed CE and Rohs certification, which is the best solution for economical digital applications.

Biosflows FDC-320 Massflow Controller and Metes Technical Parameters

| Performance | |

|---|---|

| Flow Accuracy | ±%1 F.S; ±1.5% F.S(>100 slm) |

| Repeatability | ±0.2% F.S |

| Control Range | 2%~100% F.S |

| Response Time | <2s |

| Temperature Coefficient | Zero: <0.05% of F.S./℃. Span: <0.1% of S.P. /℃ |

| Pressure Coefficient | 0.2% of S.P. / Bar |

| Operating Temperature | 0~50℃ |

| Leak Rate | 1x10-9 atm. cc/sec He |

| Preheat Time | 5 min accuracy to ±2% F.S (30 min to achieve the best accuracy) |

| Electrical Parameters | |

| Power Supply | +15~24 V dc |

| Maximum Power Consumption | 10W(MFC);3W(MFM) |

| Digital Communication | RS-485(modbus Rtu) |

| Analog Communication | 0~5 V / 4~20mA |

| Electrical Interface | 9-pin D-connector (male) |

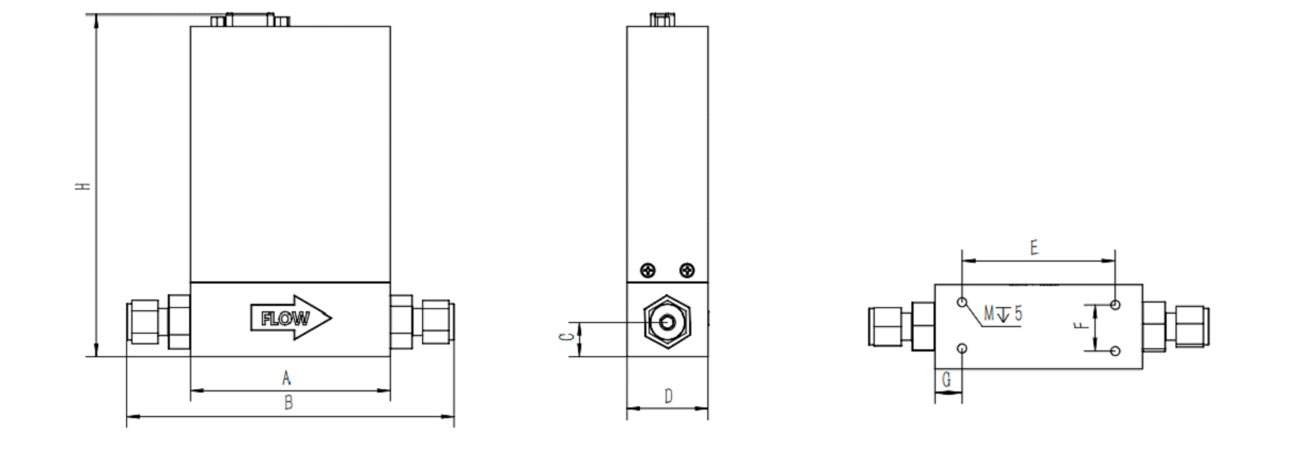

| Mechanical Parameters | |

| Valve Type | Normally closed (MFM meaningless) |

| Substrate Material | 316L stainless steel |

| Sealing Material | FKM, EPDM, BUNA |

| Process connections | Tube/VCR Fittings |

Features of FDC-300 Series Mass Flow Controller and Meters

Long-term Stability and Accuracy

Unique thermal sensing technology can provide excellent signal-to-noise ratio performance to improve measurement and control accuracy under low set-point conditions Long-term zero point stability, annual variation is less than 0.2% of full scale.

Multiple Communication

This series is equipped with a digital circuit system, which is compatible with analog signals 0~5V/4~20mA, but also can communicate through RS-485 digital communication. The multi-protocol communication interface can simplify the integration operation.

Resistant to Toxic and Corrosive Gases

The capillary thermal temperature difference sensor effectively isolates the erosion of corrosive gases. The substrate is made of 316L stainless steel, and the chemical corrosion-resistant valve has super adaptability to toxic and corrosive gases.

Wide Pressure and Flow Range

The flow range of this series can be from 3 sccm to 2500 lpm, and the pressure resistance rating and working pressure are also up to 500 psi/100 bar. The high pressure differential solenoid valve is suitable for flow measurement and control.

Modular Design for Easy Maintenance

A user-accessible service port simplifies installation, troubleshooting, and diagnostics without interfering with flow controller operation, and a durable, stable metal housing prevents damage to the unit during installation.

Application of FDC-300 Series Mass Flow Controller and Meters

Petrochemical Reaction System

In order to optimize a chemical reaction, the best combination of compounds must be found and injected into the reactor in an optimal ratio. A certain pressure and temperature can be maintained, and a catalyst can be added to accelerate the reaction. When the reactor is pressurized, the incoming reaction gases must always be accurately measured.

Gas Chromatographs Instrument

Gas chromatography is a widely used analytical technique for qualitative and quantitative analysis of samples. The sample is injected through the sample injector in the carrier gas flow. Gas flow is controlled using a high-precision mass flow controller. The sample to be analyzed will pass through a stationary heated column, eluting the analytes at different times.

Material Preparation Process Applications

In the preparation of some new materials, such as graphene and diamond crystals, chemical vapor deposition is usually used. The gas mass flow controller can accurately control the gas flow in the reaction chamber of the equipment to improve the purity of the prepared crystals. Thereby ensuring product quality. Welcome to visit our company freely.

Ar Protection System for Steelmaking

There must be sufficient supply of argon in the process of smelting steel. On the other hand, since argon is expensive, the supply must be limited and well controlled. In addition, when the pressure in the converter changes, the air supply control equipment must be able to compensate for this. Gas lines and shut-off valves are to be arranged by the customer.